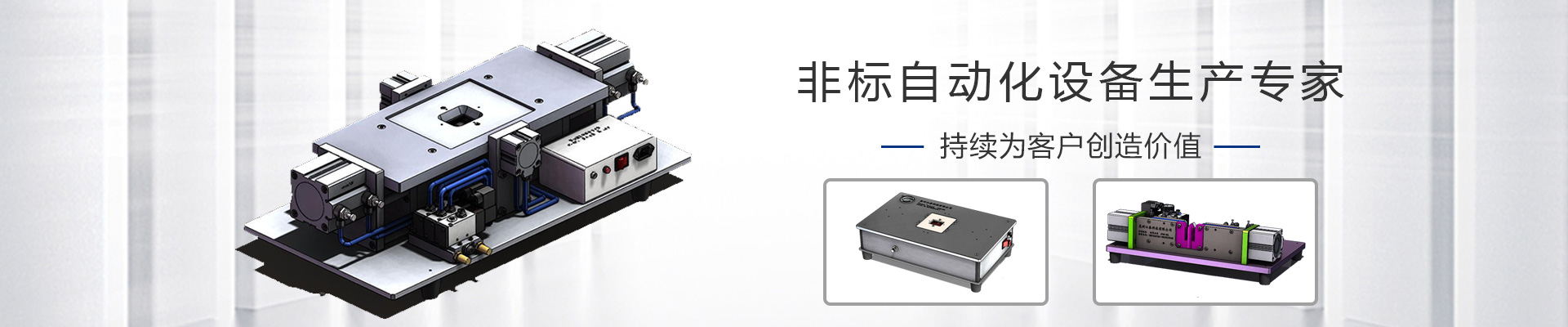

Instruction manual for pull shear molding machine

JT25-27L tensile shear molding integrated machine; It is a self-developed equipment by our company for pulling and shearing magnetic ring inductor pins; This model is specifically designed for T6X3X3, T9X5X3, T10X6X5, etc This model is a commonly used magnetic ring inductor design with a wire diameter of 0.4MM-1.0MM. It provides the ability to complete stretching, shearing, and shaping work, with the entire process completed in 0.3 seconds. A circular inductor pin cutting and shaping equipment with high processing efficiency, good product quality, and reduced labor costs. Due to its stable equipment and wide adaptability, it is loved by the circular inductor processing industry.

Exclusive patent: ZL 201720430140.1

2、 Main features

◆: Overall compact and compact, the panel is made of top-notch steel material, with a surface electroplated and hardened treatment, and the design surface is flat; Designed in accordance with ergonomics, hands will not feel tired after prolonged operation; Aluminum alloy sandblasting oxidation chassis, making the overall weight lighter and appearance more beautiful;

◆: The wire outlet is protected by a 4mm thick steel plate. Protect the machine's cutting blades from injuring hands. Safer operation;

◆: Panel embedded pressure gauge, intuitive tension;

◆: A tension adjustment knob is designed behind the frame to adjust the tension for different types of magnetic rings and wire sizes:

◆: Adopting high-quality dual axis cylinders, stable operation, strong cutting force, and fast speed.

◆: Wide compatibility, the small ring can be directly formed, and can be used to shape and repair the upper bottom plate and soldered products. Directly replace the old molding foot clipper.

◆: Using a regular 0.8mpa air compressor air source. 220V power input.

3、 Installation instructions

1. The filter regulator should be installed vertically, with the left side connected to the air compressor and the right side connected to the machine, with a pressure of 0.4-0.45MPA (which has been adjusted at the factory and should not exceed 0.5MPA). Otherwise, the cutting blade may not cut or pull straight;

2. Observe whether there is water in the jar every day, drain the water from the top and bottom of the jar, and push out the water from the top pin to prevent water from entering the solenoid valve and damaging the components.

Attention: The stabilizing filter cannot be connected in reverse. It is fixed and cannot be adjusted. Check the moisture content every day

4、 Function Description

1: Pressure display - displays the current tension of the wire clamp. The higher the value, the tighter the wire is pulled;

2: Capacity display - displays the current output. (Only the aluminum alloy panel version comes with this function)

3: Tension adjustment - Adjust the clamping force of the product pins. (1 pressure gauge display) The higher the adjustment, the tighter the pulling, and the more beautiful the foot position. Note that adjusting too high may cause pin breakage; Some products may also experience poor pressure resistance; Or some products with thicker threads (0.8mm or above) may experience the phenomenon of the cutter not cutting. Adjust the appropriate tension according to the actual situation of each different product.

4: Air source interface - connect to the voltage stabilizing filter included with the machine (the filter must be connected, otherwise water entering the machine will damage the equipment in advance)

5: Household 220V power interface

6: Power switch - If the equipment is parked for a long time and the fixture is replaced, the power must be turned off

7: Foot switch interface - connected to the attached 2-pin foot switch

8: Production reset button (some are start buttons depending on version)

9: Speed adjustment, pressure compensation knob. The slower the speed, the greater and more stable the tension compensation. Conversely, the faster the speed, the smaller the tension. The factory has been adjusted to the most suitable state, and there is no need to adjust the wire diameter below 0.8.

5、 Replace the fixture

1: First, turn off the power. Loosen the bolts on the fixture cover plate, take out the fixture cover plate, and then install the complete set (5 pieces+1 fixture head) of fixtures in sequence; Be sure to turn off the power before operating

2: When installing the fixture, first install the matching fixture head under the chassis, and then install 5 fixtures in sequence. Cover the fixture cover plate,

Attention: After covering the fixture cover, put on the screws of the fixture cover, twist the screws in place by hand without tightening them, and then turn on the power switch. Step on the foot switch and tighten the screws. Twisting too tightly may cause deformation of the cover plate, affecting the normal operation of the fixture

3. Replace the fixture head: Then turn the equipment upside down and replace the bottom fixture head;

1. Loosen the half circle fixed pressure plate screw, rotate the fixed pressure plate, and use pliers to clamp out the fixture head;

Attention: The fixing plate bolt cannot be completely twisted off, just half a turn is enough, otherwise it will be difficult to install it back

6、 Regular maintenance

This equipment must pay attention to maintenance, oiling, and lubricating the moving parts. Maintain and oil at least once a week. Open the fixture cover plate.

Attachment: One filter regulator, one power cord, one foot switch, one 3MM hex wrench, and one bottle of lubricating oil. Attention: The air source filter regulator must be installed within a distance of 2 meters from this equipment. Install vertically facing the pressure gauge bottle downwards. Connect the air compressor on the left and the equipment on the right. Adjust the pressure to around 0.4MPA, not exceeding 0.5MPA (already adjusted at the factory), and pay attention to regularly draining the water inside the tank.